In the world of modern production, the function of machinery in the handling of metal is both vital and transformative. From the elaborate layout of building walls to the architectural integrity of ceilings, makers like the metal wall panel machine and metal ceiling perforation line are at the center of innovation. These equipments simplify the fabrication and handling of various metal elements, ensuring performance and quality that satisfies the high standards of today's commercial needs. Among these, the metal perforated machine sticks out for its flexibility, permitting manufacturers to create items with varying hole sizes and patterns, which not only add to aesthetic allure however likewise practical requirements such as weight decrease and airflow.

The significance of coil perforation lines can not be overemphasized, as they facilitate the processing of metal coils into usable sheets or elements with pre-determined openings. Paired with advancements in innovation, today's sheet metal perforating machine can accomplish high speeds and performance, enabling for massive manufacturing without endangering top quality.

Furthermore, as style aesthetics end up being a significantly significant aspect in style, the demand for metal ceiling floor tiles has actually surged. This is where the ceiling T-grid machine comes right into play. By automating the production of T-grids, it simplifies the installation of suspended ceilings, offering not just useful assistance for the ceiling tiles but likewise boosting the total design without the added complexity of hands-on labor. The precision design associated with these devices makes sure smooth links and placements, which are crucial for the finished appearance of any space.

To even more boost metal construction capacities, producers often rely upon complementary tools such as the metal sheet leveling machine and sheet metal straightening machine. These devices play a critical duty in making certain that metal sheets are cost-free and flat from any kind of bending or defects, which can lead to issues in subsequent processing phases. A well-leveled sheet is paramount in applications needing precision, as even small disparities can detrimentally influence joint stability in welding or lower performance in succeeding cutting procedures.

As we dive deeper right into the efficiency of these equipments, it is worth keeping in mind that the advancement in electronic innovation has yielded a new age in the operation of metal processing tools. Several makers today are furnished with CNC (Computer Numerical Control) systems, enabling better personalization, automation, and precision. This shift to CNC-controlled metal sheet perforating equipments and perforation lines improves the manufacturing process by allowing drivers to quickly adjust specifications and setups, thus suiting differing task needs without substantial retooling.

The combination of clever technology and IoT (Internet of Things) right into producing procedures likewise contributes to operation effectiveness. Lots of modern-day perforation machines include functions such as real-time surveillance and data analytics capabilities, equipping operators to make educated decisions regarding upkeep, manufacturing rate, and high quality control. This not only simplifies operations however can additionally cause anticipating maintenance, reducing downtime by addressing potential issues before they rise into significant issues.

As the market for made metal items remains to grow, the need for effectiveness, accuracy, and adaptability in metal handling devices becomes extremely important. The advancement from obsolete, manual procedures to automated systems facilitates this need by enabling makers to enhance their operations and output. Particularly, the capacity to rapidly adapt to changing layout demands or manufacturing quantities via modular systems in devices like the coil perforation line has actually transformed just how organizations operate.

In enhancement to useful applications, the environmental read more effect of making processes is an additional essential variable to take into consideration. Devices like the metal wall panel machine and perforated equipments have the potential to lessen waste product through much more reliable designs and handling approaches. Accountable suppliers are discovering means to recycle scrap metal created during the perforation and forming procedures, thus lowering their general carbon impact. Making use of sophisticated modern technologies to make best use of material usage straightens with the growing emphasis on sustainability in making practices.

As markets strive for even more environment-friendly solutions, the metals made use of additionally evolve. The trending preference for eco-friendly materials and recycled steels highlights an additional layer of intricacy in the machinery used for metal processing. Modern equipment should not just suit traditional metal types however additionally adapt to the nuances provided by brand-new, lasting products while maintaining performance and high quality.

As we want to the future of metal construction, the constant advancement of makers such as the ceiling T-grid machine and the metal ceiling perforation line will play an essential function in forming sector criteria and methods. The ongoing technology in automation, paired with innovative product scientific research, settings makers to check out innovative opportunities in layout and building and construction that were formerly unattainable.

Eventually, the interconnected ecological community of machinery-- including the sheet metal perforating machine, metal sheet here leveling machine, and others-- produces an atmosphere ripe for development. By accepting these technological improvements, makers are not just boosting their manufacturing abilities however are likewise establishing a new frontier for what is possible in metal fabrication. The harmony of accuracy engineering, automation, and wise innovation is enabling businesses to grow in an affordable landscape, thus preparing for a more liable and efficient manufacturing future.

The significance of coil perforation lines can not be overstated, as they facilitate the handling of metal coils right into functional sheets or components with pre-determined perforations. This procedure dramatically boosts the versatility in design and application, dealing with varied markets such as construction, auto, and home appliances. The accuracy supplied by such devices ensures that each perforation is executed with precision, consequently reducing waste and making the most of resource application. Combined with advancements in technology, today's sheet metal perforating machine can accomplish high speeds and efficiency, permitting large-scale manufacturing without endangering high quality.

The assimilation of wise innovation and IoT (Internet of Things) into making procedures also contributes to procedure efficiency. Numerous modern perforation makers include features such as real-time surveillance and information analytics capabilities, encouraging operators to make informed choices about upkeep, production rate, and quality assurance. This not just improves operations yet can also cause predictive maintenance, lowering downtime by attending to prospective issues prior to they escalate right into significant issues.

In verdict, as we reflect on the importance of devices like the metal wall panel machine, metal ceiling perforation more info line, and various other related devices, it is clear that they stand for much more than simple devices; they personify the potential for development and development in the metalworking market. With proceeded investment in these technologies, the future of metal processing looks encouraging, supplying exciting possibilities for both producers and end-users alike.

Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Elisabeth Shue Then & Now!

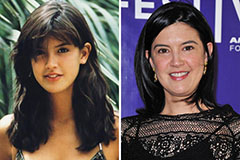

Elisabeth Shue Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now!